Superhydrophobic Composite Asymmetric Electrospun Membrane for Sustainable Vacuum Assisted Air Gap Membrane Distillation

Abstract

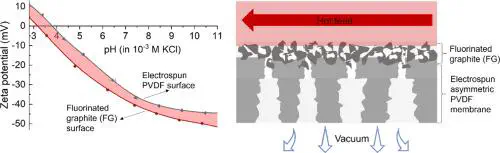

Membrane distillation (MD) relies on superhydrophobic membranes that must achieve the competing goals of high liquid entry pressure (LEP) and high permeability. In this study, we developed the first superhydrophobic composite electrospun asymmetric membrane using fluorinated graphite (FG). We also provided among the first comparisons of the relative benefits of membrane asymmetry and composite coatings via 3D electrospinning and spraying. FG particles increased the roughness and reduced the zeta potential of the membranes. Superhydrophobic composite membranes had a contact angle of 157$^∘$ (sliding angle of 7$^∘$) and an LEP of 327,kPa. Long-term MD testing revealed that FG particles could increase MD’s sustainability while decreasing membrane wetting. Vacuum-assisted air gap membrane distillation (V-AGMD) showed that the composite asymmetric membrane outperformed the non-asymmetric version (composite nanofiber) membrane by 21,% in average water flux and 25,% in average thermal efficiency because of the asymmetric structure of the membrane. The numerical model developed for the V-AGMD system also successfully predicted the water flux generated experimentally from the composite nanofiber and composite asymmetric membranes. Our results confirmed that electrospun asymmetric FG membranes with high contact angle, low sliding angle, high permeability, and high gained output ratio (GOR) would be promising candidates for sustainable MD.