Abstract

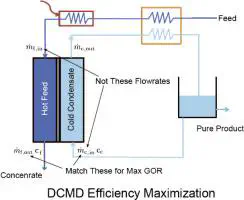

A simple theoretical method for maximizing efficiency via real-time balancing of direct contact membrane distillation (DCMD) systems is presented. The method is applicable under variable operating conditions. Balancing involves measuring only the flow rates of feed stream out of the module and the cold water flow into the module, as well as the salinity of the feed. A valve or variable frequency drive is used to set the condensate water flow into the module so that the heat capacity rates of the hot and cold streams are equal. This method is much simpler and more general than what is proposed in the literature, which generally requires more measurements and a complicated expression. Balancing leads to 20–50% improvement in efficiency (GOR) compared to equal inflow of both feed and pure water streams, which is the common practice. Real-time balancing is particularly useful for variations in feed salinity, whereas the improvement by real-time balancing is low for changes in system top or bottom temperatures.